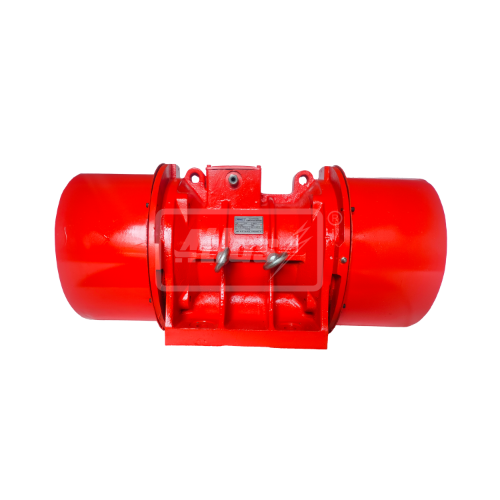

Vibrating Motors

| Category | Details |

|---|---|

| Company Name | AMIT ELECTRICALS |

| Brand | Atlas |

| Product Name | Vibrating Motor |

| Operation | Three-phase or single-phase synchronous motor with eccentric (unbalance) weights to create vibration |

| Design | Rotor shaft with adjustable eccentric weights; creates centrifugal force to generate vibration |

| Range of Production |

Three Phase: 0.25 to 15 HP (0.18 to 11 KW), 2 to 12 poles, 415 ±5%, 50Hz ±3% Single Phase: 0.25 to 2 HP, 2 or 4 pole, 215 ±5%, 50Hz ±5% (110V optional) |

| Mounting Types | Foot Flange Center Flange |

| Frame Material | Rugged steel casting with integral feet |

| Insulation | Class F (Standard), Class H (on request) |

| Ratings | S1 – Continuous Duty |

| Voltage & Frequency | Standard: 415V 3ph, 50Hz Optional: 220V, 380V, 460V, 525V at 50 or 60 Hz |

| Protection | IP44 (Standard), IP54/IP55 on request |

| Shaft & Rotor |

Shaft: High carbon steel Rotor: High-pressure E.C. grade aluminum die-cast, dynamically balanced |

| Bearings & Lubrication |

Permanently lubricated bearings Large motors re-lubricable with special grease |

| Thermal Overload Protection | Optional T.O.P. switch available on request |

| Terminal Box | Standard top terminal box; custom options on request |

| Earthing Terminals | Minimum two terminals |

| Enclosure | T.E.S.C. (Totally Enclosed Surface Cooled) |

| Paint | Semi-gloss synthetic enamel (custom on request) |

| Application | Mining, Food, Construction, Pharma, Ceramic, Foundry, Steel, Chemical, Recycling, Plastic Industries |

| Features |

Highly efficient Durable Smooth finishing Economical price Precision design Long life |

Vibrating Motors – Reliable Vibration for Industrial Material Handling

What Are Vibrating Motors?

Vibrating motors are specially designed electric motors that generate mechanical vibration using an unbalanced weight attached to the rotor. These vibrations are crucial for applications involving the movement, separation, or compaction of materials—such as feeders, screens, compactors, and hoppers.

At Atlas Electrical, our vibrating motors are engineered for high performance, long life, and maintenance-free operation in even the most demanding industrial environments.

Key Features of Vibrating Motors

1. Adjustable Centrifugal Force

The vibration strength can be adjusted by changing the position or angle of the eccentric weights mounted on either end of the shaft.

2. Robust & Dustproof Design

Atlas vibrating motors come with rugged enclosures and sealed bearings, making them resistant to dust, moisture, and harsh environmental conditions.

3. Compact and Easy to Install

Their compact, space-saving design allows easy integration into machinery with limited space and complex layouts.

4. Continuous Duty Rating

Built for 24/7 operation, these motors are ideal for continuous duty cycles without performance degradation.

Benefits of Using Vibrating Motors

1. Efficient Material Movement

Whether it’s for feeding, screening, or compacting, vibrating motors provide the mechanical energy required to handle materials with precision and consistency.

2. Low Maintenance Requirements

Designed with high-quality materials and sealed lubrication, our motors minimize downtime and reduce operational costs.

3. High Operational Safety

Vibrating motors from Atlas Electrical are thermally protected and dynamically balanced to ensure safe, stable, and quiet operation.

4. Custom Vibration Settings

Depending on your application, the frequency and amplitude of vibration can be fine-tuned for optimal performance and energy efficiency.

Applications of Vibrating Motors

Vibrating motors are vital across a wide range of industries and applications, including:

- Vibratory Feeders and Conveyors

- Screening Machines and Sieves

- Hopper Dischargers

- Compaction Tables and Moulding Machines

- Concrete Block and Precast Plants

- Pharmaceutical and Food Processing Equipment

- Mining and Quarry Equipment

From granular flow control to industrial compaction, these motors ensure smooth, controlled, and consistent performance in material handling systems.

How to Choose the Right Vibrating Motor

Determine Required Centrifugal Force

Match the force output (measured in kgf or N) to the machine’s weight and the material’s flow characteristics.

Select the Correct Speed

Atlas vibrating motors are available in multiple speeds (e.g., 750 RPM, 1000 RPM, 1500 RPM, 3000 RPM) to suit light, medium, and heavy-duty applications.

Mounting Orientation

Choose from foot-mounted, flange-mounted, or custom-built models based on your machine’s design and available space.

Motor Rating and Protection

Ensure the motor’s insulation class, IP rating (typically IP55 or IP65), and duty cycle match your environmental and operational needs.

Why Choose Atlas Electrical’s Vibrating Motors?

At Atlas Electrical, we manufacture high-performance vibrating motors that meet the most demanding requirements of modern industry. Here’s what sets us apart:

- ISI-certified and industrial-grade quality

- Wide range of vibration forces and RPMs available

- Robust cast iron or aluminum construction options

- Dynamically balanced for long-lasting operation

- Expert technical guidance and fast delivery support

Whether you’re in construction, food processing, mining, or manufacturing, our motors deliver the power and reliability your machinery depends on.

Conclusion

A high-quality vibrating motor is essential for effective material flow, separation, and compaction across various industrial processes. With Atlas Electrical’s durable, efficient, and customizable vibrating motors, you ensure continuous productivity, lower maintenance, and precise material control.

Choose Atlas for vibration you can trust—engineered for performance, built for industry.

Product Features & Configuration

Amit Electricals manufacturer, exporter and supplier of vibrating motors. The external vibrator is a three phase or single-phase synchronous motor that has eccentric weights (unbalance weight) mounted at the ends of the Rotor shaft. The rotating shaft causes centrifugal forces, which can be adjusted by moving the weights it create a vibration. It also calls Vibratory motor, Unbalance Motor, vibro motor, vibrates motor Ect. Vibration Help Many Ways in Machine Application like Compacting, conveyor, assorting ect.

RANGE OF PRODUCTION

Three Phase Motor

We having wide production range of vibrating motor 0.10 to 15 Hp. (0.075 to 11 K.W.) in 2, 4, 6, 8, 10 & 12 Pole. In Three Phase Vibrating Motor Supply volts 415 ± 5% 3 phase 50 Hz. ± 3% we are also capable for manufacturing vibrating motor in different volts and frequency Like 220, 380, 460, 525 in 50 or 60 Hz.

Single Phase Motor

0.25 H.P. TO 2 H.P. in 2,4 pole 1 phase supply volts 215 ± 5% 50Hz. ± 5% on customer request we are also able supply motor in 110 volts on 50 or 60 Hz Also.

Mounting Type

- Foot

- Flange

- Center Flange

Features

- Highly efficient

- Durable

- Smooth finishing

- Economical price

- Precision design

- Long Life

Frame

All Vibrating motor are supplied in a robust, rugged steel casting frame with integral feet.

Ratings

All Vibrating motors are continuous (S1) rated.

Design

The Vibratory Motors is a three-phase synchronous motor that has eccentric weights (unbalance weight) mounted at the ends of the Rotor shaft. The rotating shaft causes centrifugal forces, which can be adjusted by moving the weights it create a vibration.

Vibration Proof Motor Winding

Vibratory Motors Insulation class F enhances the safety under continuous operation conditions and at high ambient temperatures. Motor is tropicalized and designed for an extended voltage range.

Protection

We are supplying motor with Ingress protection 44. Vibrating Motors can be supplied with IP-54 and IP-55 on request.

Insulation

Vibrating motor are supply with class B & F insulation as standard feature. Also supply H on request of customer.

Rotor

All Vibrating motor Rotors are of high-pressure E.C. Grad aluminum die-cast. Every rotor is dynamically balanced. It’s made motor low amplitudes of Vibration & noise

Shaft

Shaft made from high carbon steel to provide exceptional Strength & rigidity to minimize deflection. Motor Rotor is positive locking with joint so that cannot move on high Full lord Torque.

Bearings & Lubrication

Vibratory Motors the right type of bearing for every application guarantees long service life even continuous operation. All vibratory motors are permanently lubricated for normal operation. Large capacity motor can be re-lubricated for average application. Sp. Type of grease is used in vibratory motor.

Enclosure

Vibrating motor Supply with Enclosure T.E.S.C. (Totally Enclosed surface Cooled)

Thermal Over protection

We can also supply motor with T.O.P Switch on Demand of Customer. It can provide motor extra safety form over lord protection.

Earthing Terminals

All Vibrating motor provided with minimum two earthling terminals.

Paints

All Vibrating motors are painted with semi glossy synthetic enamel paint. However sp. Paint is available on request.

Application

Mining Industry, Food Industries, Construction, Parma industries, ceramic Industries, Foundry, Steel Industries, Chemical Industries, Recycling industries, Plastic Industries, Ect.