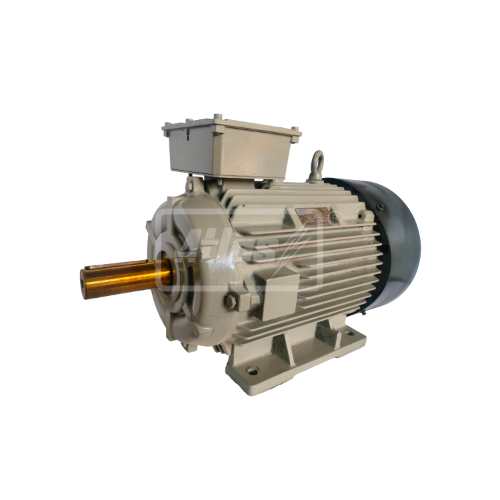

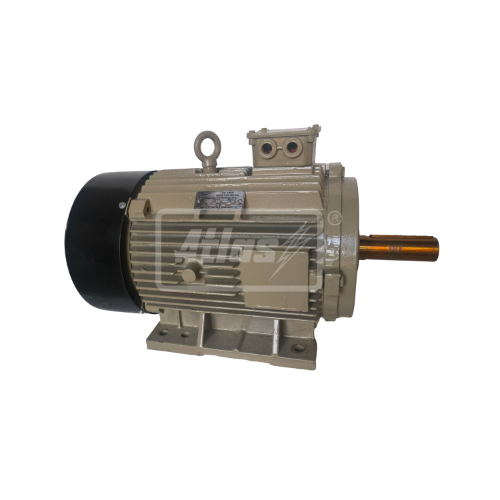

Inverter Duty Motor

| Category | Details |

|---|---|

| Company Name | AMIT ELECTRICALS |

| Brand | Atlas |

| Product Name | Inverter Duty Motor |

| Operation | For operations requiring wide speed variation through variable frequency drives |

| Range of Production |

Power: 0.10 to 75 Hp (0.075 K.W. to 55 K.W.) Frame: 63 to 250M Poles: 2, 4, 6, 8, 10, 12 |

| Mounting Types |

Foot (B3) Flange (B5) Face (B14) Foot with Flange (B35) Foot with Face (B34) |

| Frame Material | Rugged cast iron frame with integral feet. Aluminum body available up to 100L frame (on request) |

| Insulation | Class F (Standard) Class H (on request) |

| Voltage & Frequency |

Standard: 415 ± 5%, 50 Hz ± 3% Optional: 220, 380, 460, 525 V at 50 or 60 Hz (on request) |

| Protection |

IP44 (Standard) Optional: IP54, IP55 (on request) |

| Shaft & Rotor |

Shaft: High carbon steel for strength and rigidity Rotor: High-pressure E.C. Grade aluminum die-cast Dynamically balanced to reduce vibration & noise |

| Bearings & Lubrication |

Bearings: C3 ball bearings Lubrication: Lithium-based grease (up to 150°C) |

| Thermal Overload Protection | Optional T.O.P. switch available on customer request |

| Terminal Box | Top position for Foot mounted (B3). Other positions (left/right) available (on request) |

| Earthing Terminals | Minimum two: one in terminal box, one on foot |

| Application | Suitable for lifting machinery, textile machinery, geared motors, cable reeling drums, rolling mills, and machine tools |

| Features |

Optimum performance Durability Low maintenance cost Energy-efficient Noise-free Vibration-free |

Product Features & Configuration

Amit Electricals manufactures supplier and exporter of Inverter Duty motor. Inverter duty specially winding designed for operations requiring wide speed variation through variable Frequency drives. These motors are generally used when the motor is running for longer duration at speeds below 70% of rated name plate speed.

Amit Inverter duty motors operate at constant torque up to rated design frequency when connected with variable frequency drives.

RANGE OF PRODUCTION

0.10 to 75 Hp. (0.075 K.W. to 55 K.W.) Frame 63 to 250M in 2, 4, 6, 8, 10 & 12 Pole

Mounting Type

- Foot (B3)

- Flange (B5)

- Face (B14)

- Foot with Flange (B35)

- Foot with Face (B34)

Features

- Optimum performance

- Properly insulated

- Durability

- Low Maintenance cost

- Energy efficient

Standards

Inverter Duty motor Performance conforms to Is: 325 and dimensions according to IS 1231 & IS 2223

Frame

Inverter Duty motor is supplied in a robust, rugged cast iron frame with integral feet. On Request we can supply motor in aluminum body up to 100 L frame.

Ratings

All Standard Inverter Duty motors are continuous rated to comply with performance standards.

Voltage and Frequency

Supply volts 415 ± 5% 3 phase 50 Hz. ± 3% We are also capable for Manufacturing three phase motor in different volts and frequency Like 220, 380, 460, 525.

Protection

We are supply Inverter Duty motor with Ingress protection 44 as defined in IS: 4691. Motors can be supplied with IP-54 and IP-55 on request.

Thermal Overload Protection

We can also supply Inverter Duty motor with T.O.P Switch on Demand of Customer. It can provide motor extra safety form over lord protection.

Cooling

Inverter Duty motor is fitted with separate cooling arrangement which ensures that the motors perform successfully at lower speeds without over-heating of the motor. This also ensures that the loading capacity of the motor is not reduced in this range.

Insulation

Inverter Duty motor supply with class F insulation as standard feature. Also supply H on request of customer.

Shaft

Inverter Duty motor Shaft Made from high carbon steel to provide exceptional Strength & rigidity to minimize deflection.

Rotor

Rotors are of high-pressure E.C. Grad aluminum die-cast. Every rotor is dynamically balanced. Its make motor low amplitudes of Vibration & noise

Bearings & Lubrication

Inverter Duty motor Bearings are adequately lubricated with lithium based high temp up to 150 deg. All the Inverter Duty motor are supplied with C3 ball bearing & fully charged with lithium base grease at the time of assembly.

Terminal Box

All Inverter Duty motor Supply with Terminal box on top position For Foot mounted (B3). Other position box like left or right supply on customer request

Earthling Terminals

Inverter Duty motor provided with minimum two earthling terminals. One in the terminal box and other on foot.