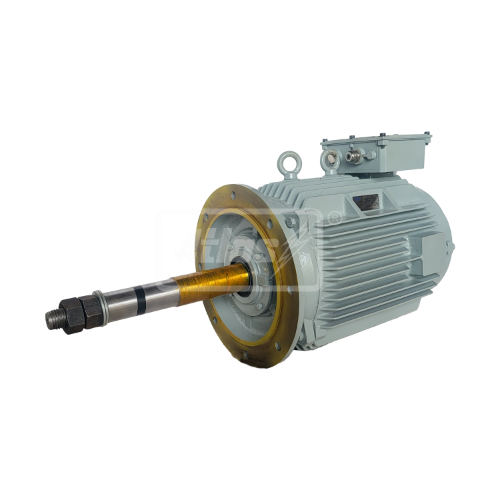

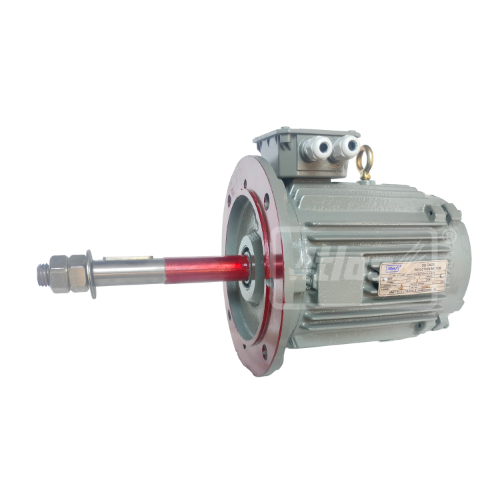

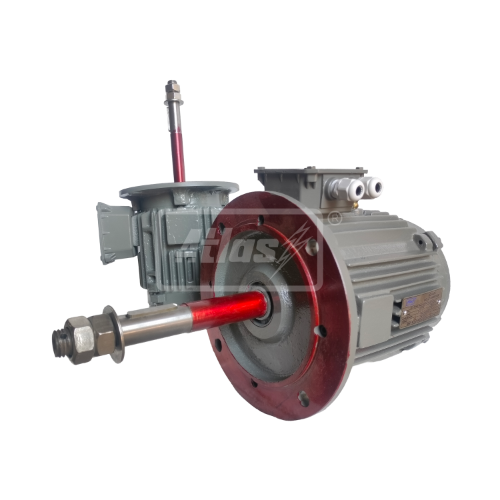

Cooling Tower Motor

| Category | Details |

|---|---|

| Company Name | AMIT ELECTRICALS |

| Brand | Atlas |

| Product Name | Cooling Tower Motor |

| Application | Specifically designed for cooling tower fan operations in high humidity areas like industrial hvac, textile machinery, plastic machinery |

| Range of Production |

Power: 0.25 to 25 HP (0.18 to 18.5 KW) Frame: 63 to 250M Poles: 4, 6, 8, 10, 12 Speeds: 1500, 1000, 750, 600, 500 RPM @ 50 Hz |

| Mounting Types | Flange (B5) |

| Frame Material | Robust cast iron frame |

| Ratings | S1: Continuous Duty |

| Voltage & Frequency |

Standard: 415 ± 5%, 3 Phase, 50 Hz ± 3% Optional: 220, 380, 460, 525 V at various frequencies |

| Protection |

IP55 protection Suitable for up to 90% relative humidity |

| Shaft |

Material: Stainless Steel AISI-410 Nut & Washer: Stainless Steel AISI-202 Extended shaft for fan fitting Corrosion protection |

| Insulation & Duty |

Insulation Class F Designed for continuous operation (S1) |

| Bearings & Oil Seal |

Double shielded bearings (ZZ or 2RS) Pre-lubricated with high temp grease Oil seal prevents moisture ingress |

| Enclosure | T.E.S.C. (Totally Enclosed Surface Cooled) |

| Thermal Overload Protection | Optional T.O.P. switch available on demand |

| Earthing Terminals | Minimum two: one in terminal box, one on body |

| Paint | Semi-glossy synthetic enamel (special paints available on request) |

| Features |

Highly efficient Durable Smooth finishing Economical price Precision design Long life |

Cooling Tower Motor – Engineered for Harsh Environments & Maximum Uptime

What Is a Cooling Tower Motor?

A cooling tower motor is a specialized electric motor designed to operate in wet, humid, and demanding outdoor environments typically found in industrial and HVAC cooling systems. These motors power the fans in cooling towers that help dissipate heat from chillers or industrial processes, ensuring efficient thermal management.

Key Features of Cooling Tower Motors

Cooling tower motors are built differently from standard motors to handle the unique challenges of outdoor, moisture-prone environments. The main features include:

1. Weather-Resistant Design

These motors come with specially treated enclosures and anti-corrosive coatings, making them ideal for operation in high-moisture areas.

2. High Starting Torque

To handle the fan blades’ inertia and start under heavy load conditions, cooling tower motors are designed with high starting torque capabilities.

3. TEFC or WP-I Enclosures

Cooling tower motors often come in Totally Enclosed Fan Cooled (TEFC) or Weather Protected Type I (WP-I) enclosures for added protection from water ingress, dust, and debris.

4. Thermal Overload Protection

Integrated thermal protection ensures the motor doesn’t overheat during prolonged operations, especially in fluctuating ambient temperatures.

Benefits of Using a High-Quality Cooling Tower Motor

1. Durability in Harsh Conditions

Cooling tower motors are engineered to resist rust, corrosion, and environmental wear—perfect for outdoor installations.

2. Energy Efficiency

Atlas Electrical’s cooling tower motors are designed for low power consumption, helping you reduce energy costs while maintaining reliable performance.

3. Low Maintenance

Thanks to sealed bearings and robust construction, these motors require minimal maintenance, resulting in reduced downtime and lower total cost of ownership.

4. Quiet Operation

Precision-engineered components reduce vibration and noise, making them suitable for commercial buildings and sensitive environments.

Applications of Cooling Tower Motors

Cooling tower motors are a critical component across various industries and systems, including:

- HVAC Systems in Commercial Buildings

- Power Plants and Energy Facilities

- Chemical and Petrochemical Industries

- Manufacturing and Process Industries

- Data Centers

- Cold Storage Units

Wherever heat must be efficiently dissipated, a reliable cooling tower motor plays a key role in ensuring optimal performance.

Choosing the Right Cooling Tower Motor

Before selecting a cooling tower motor, assess the following specifications to match your application needs:

Motor Power Rating

Available in various horsepower (HP) and kilowatt (kW) ratings, depending on the size and capacity of your cooling tower.

Mounting Type

Cooling tower motors can be foot-mounted, flange-mounted, or customized to fit specific cooling tower fan assemblies.

Speed & Torque Requirements

Ensure the selected motor delivers sufficient torque and operates at the right RPM for maximum efficiency and airflow.

Enclosure and IP Rating

Choose a motor with appropriate ingress protection (IP55 or higher) and enclosure type based on your environmental conditions.

Why Choose Atlas Electrical for Cooling Tower Motors?

At Atlas Electrical, we offer a complete range of cooling tower motors tailored for high performance, safety, and durability. When you choose our motors, you get:

- ISI-certified quality and performance assurance

- Corrosion-resistant materials for long-term outdoor use

- Energy-efficient designs aligned with industry standards

- Customizable options to fit your cooling tower’s requirements

- Expert guidance and technical support from selection to installation

Our motors are trusted by industries across India for their reliability and low maintenance operation, even in the harshest weather conditions.

Conclusion

A cooling tower motor is an essential investment for any business relying on large-scale cooling systems. With superior build quality, resistance to environmental factors, and high energy efficiency, Atlas Electrical’s motors deliver lasting performance and value.

Product Features & Configuration

Amit Electricals Manufacturer, Exporter and Supplier of “ATLAS” Brand cooling tower motor. Cooling tower motors are special design for Cooling Tower Fan. Cooling tower motor specially designs for work in humidity area at continually.

RANGE OF PRODUCTION

We have wide production range of Cooling Tower motor 0.25 To 20 Hp. (0.18 to 20 K.W.) Frame 63 to 250M in 4, 6, 8, 10 & 12 Pole (1500, 1000, 750, 600 and 500 RPM at 50 Hz.).

Mounting Type

- Flange (B5)

Features

- Highly efficient

- Durable

- Smooth finishing

- Economical price

- Precision design

- Long Life

Frame

Cooling Tower Motor Supply volts 415 ± 5% 3 phase 50 Hz. ± 3% We are also capable for Manufacturing three phase motor in different volts and frequency Like 220, 380, 460, 525.

Voltage and Frequency

Cooling Tower Motor Supply volts 415 ± 5% 3 phase 50 Hz. ± 3% We are also capable for Manufacturing three phase motor in different volts and frequency Like 220, 380, 460, 525.

Ratings

All Cooling Tower Motors are continuous (S1) rated to comply with performance standards.

Protection

We are Providing Cooling Tower Motor with IP55. Motors relative humidity up to 90%.

Shaft

Cooling Tower Motor Shaft is Mead by stainless steel material AISI-410. Nut and washer are made for stainless steel AISI-202. It can make protection against corrosion. Motor shaft extended so cooling fan fitted properly.

Duty & Insulation

Centrifugal switch is hart of Single phase motor. A centrifugally operated automatic Mechanism used in conjunction with split phase and other type of single-phase induction motors. Centrifugal cutout switches will open or disconnect the starting winding when the rotor has reached a predetermined speed and reconnect it when the motor speed falls below it. Without such device, the starting winding is susceptible to rapid overheating and subsequent burnout.

Bearing and Oil Seal

Oil Seal fitted with Flange & Shaft so that out of reach water partial or moisture inside Cooling Tower Motor motor. Bearings are double shielded (ZZ or 2RS) and pre-lubricated with high temp grease for good life of bearings.

Enclosure

All Cooling Tower motor Supply with Enclosure T.E.S.C. (Totally Enclosed surface Cooled)

Thermal Overload Protection

We can also supply motor with T.O.P Switch on Demand of Customer. . It can provide motor extra safety form over lord protection.

Earthing Terminals

All Cooling Tower Motor provided with minimum two earthling terminals. One in the terminal box and other outside on Body.

Paints

Cooling Tower motors are painted with semi glossy synthetic enamel paint. However, sp. Paint is available on request.