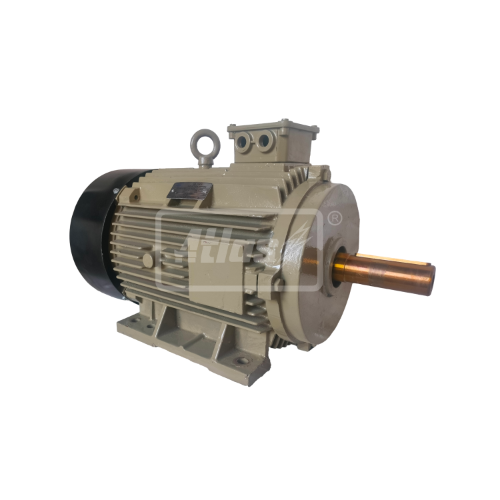

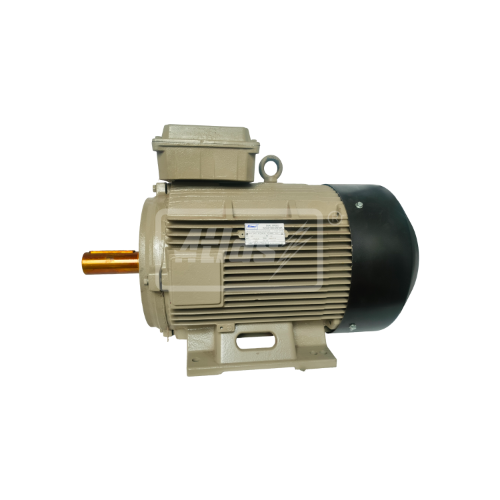

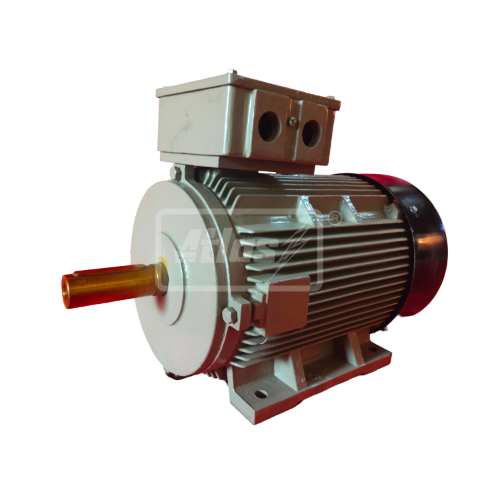

Dual Speed Motor

| Category | Details |

|---|---|

| Company Name | AMIT ELECTRICALS |

| Brand | ATLAS |

| Product Name | Dual Speed Motor |

| Manufacturing Since | 1978 |

| Power Range | 0.25 to 50 Hp (0.18 to 37 Kw) |

| Pole Configurations | 2/4, 2/6, 2/8, 4/6, 4/8, 6/8 poles (3000/1500, 3000/1000, 3000/750, 1500/1000, 1500/750, 1000/750) at 50 Hz |

| Voltage and Frequency | 415 ± 5 %, 50 Hz ± 3% (Standard); 220, 380, 460, 525 V on request, 50 or 60 Hz |

| Mounting Types | Foot (B3), Flange (B5), Face (B14), Foot with Flange (B35), Foot with Face (B34) |

| Frame Material | Robust cast iron frame with integral feet. Aluminum body available up to 100L frame on request. |

| Insulation | Class F insulation (Standard), Class H available on request. Temperature rise restricted to Class B. |

| Duty | S1: Continuous duty, S2: Short time duty, S3: Intermittent periodic duty, S4: Intermittent duty with starting |

| Protection | IP44 (Standard), Optional: IP54, IP55 on request |

| Shaft Material | High carbon steel for exceptional strength & rigidity, minimizing deflection |

| Rotor | High-pressure E.C. Grade aluminum die-cast rotors, dynamically balanced for low vibration and noise. |

| Bearings & Lubrication | C3 ball bearings, lubricated with lithium-based grease, high temperature resistance up to 150°C |

| Enclosure | T.E.F.C. (Totally Enclosed Fan Cooled) |

| Thermal Overload Protection | Optional T.O.P Switch for extra overload protection on request |

| Terminal Box | Top position for Foot mounted (B3). Custom positions available (left or right) on customer request. |

| Earthing Terminals | Minimum two: one in terminal box, one on foot. |

| Paint | Semi-gloss synthetic enamel paint. Special paint available on request. |

| Applications | Used in applications requiring multiple speeds such as pharmaceuticals, cranes, hoists, lifts, construction, chemical industries, food equipment, ceramic industries, and machine tools. Dual speed gear motors and dual brake motors are also available. |

| Features | High torque, Noise-free, High performance, Durable, Smooth finishing, Cost-effective, Precision design |

Assembly Winder Dual Speed Motor – Precision for Winding & Industrial Automation

What Is an Assembly Winder Dual Speed Motor?

An Assembly Winder Dual Speed Motor is a specialized motor designed for applications that require two different speeds for separate operations within the same machine. In industries such as textiles, cable manufacturing, and packaging, these motors enable seamless transition between high-speed and low-speed operations, enhancing precision, control, and productivity.

At Atlas Electrical, we offer robust, ISI-certified dual speed motors engineered specifically for assembly winder and winding applications.

Key Features of Assembly Winder Dual Speed Motors

1. Two Distinct Speeds in One Unit

These motors provide two preset speed options—typically achieved through pole-changing or separate windings—allowing users to alternate between fast and slow operations with ease.

2. Energy-Efficient Design

By using the lower speed only when necessary, these motors reduce power consumption, making them highly energy-efficient for repetitive industrial tasks.

3. Smooth Speed Transition

Designed with advanced internal winding configurations, the motor switches between speeds without jerks or mechanical strain, which is critical for winding tension control.

4. Low Vibration and Noise

Precision balancing and high-quality construction result in quieter, smoother operation, ideal for continuous production environments.

Benefits of Using a Dual Speed Motor in Assembly Winders

1. Better Process Control

For winding applications, switching between speeds allows precise control over yarn, wire, or film tension—preventing damage and improving product quality.

2. Compact and Cost-Effective

Using a dual speed motor eliminates the need for multiple motors or complex variable frequency drive systems, reducing space and initial cost.

3. Reduced Mechanical Stress

Smooth shifting between operational speeds lowers the mechanical stress on drive components, increasing the motor and machine’s service life.

4. Customizable Performance

These motors can be customized with speed combinations like 4/2 pole, 6/4 pole, or 8/4 pole depending on the specific needs of your winder assembly.

Applications of Assembly Winder Dual Speed Motors

Dual speed motors are highly suitable for industries that require controlled winding and unwinding operations, such as:

- Textile Winding Machines

- Cable & Wire Coiling Machines

- Film and Foil Winding Systems

- Paper and Tissue Rewinding Equipment

- Plastic Extrusion Lines

- Flexible Packaging Machinery

These motors are ideal wherever dual-stage processing (slow feeding and high-speed winding) is essential for product quality and machine reliability.

How to Select the Right Dual Speed Motor for Your Assembly Winder

Determine Required Speed Combinations

Understand your process needs—common options include 1500/750 RPM or 1000/500 RPM—based on application tension and production output.

Confirm Load and Torque Demands

Check the torque requirements for both speed levels to ensure consistent power delivery without overheating or overloading.

Evaluate Mounting and Frame Size

Choose a mounting style (foot, flange, or face-mounted) and frame size compatible with your machine’s configuration.

Assess Duty Cycle & Environmental Conditions

Make sure the selected motor is rated for the expected duty cycle (S1–S4) and can operate reliably in dusty, humid, or high-temperature environments.

Why Choose Atlas Electrical’s Dual Speed Motors?

Atlas Electrical specializes in manufacturing reliable, long-lasting assembly winder dual speed motors built to meet demanding industrial standards. Here’s why industries across India trust us:

- ISI-Certified & High-Efficiency Designs

- Custom Speed Combinations & Windings

- Durable Construction for Long-Term Use

- Quick Switching, High Torque & Low Noise

- Technical Support & Custom Engineering

From textile mills to flexible packaging units, our dual speed motors deliver the performance, reliability, and cost-efficiency you need.

Conclusion

An Assembly Winder Dual Speed Motor is a vital component in industries requiring precise, flexible, and energy-efficient speed control. With expertly engineered designs from Atlas Electrical, you gain a competitive edge in performance, quality, and reliability. Whether you’re modernizing your existing machines or building a new line, our dual speed motors offer the control and consistency your operations demand.

Product Features & Configuration

We are manufacture, exporter and supplier of “ATLAS” Make Dual speed Motor from year 1978 since Company establishment it in our products range. Dual Speed motors specially design for Working in Two different speeds. It’s designed for work in applications in which multiple speeds are required.

RANGE OF PRODUCTION

We have wide production Range in Two speed motor.

0.25 to 50 Hp. (0.18 to 37 Kw.)

Two speed motor are offer in 2/4, 2/6, 2/8, 4/6, 4/8, & 6/8 poles. (3000/1500, 3000/1000, 3000/750, 1500/1000, 1500/750 & 1000/750) At 50 Hz.

Dual sped motor available in single winding 2/4, 4/8, 4/6 and 6/12 other pole in double winding. Two speed motor are suitable to 415 ± 5 % 50 Hz ± 3% Combined ± 6 %. On customer request we are also able supply motor in 220, 380, 460, 525 volts on HZ. 50 or 60 also

Mounting Type

- Foot (B3)

- Flange (B5)

- Face (B14)

- Foot with Flange (B35)

- Foot with Face (B34)

Features

- High Torque

- Noise Free

- High performance

- Durable

- Smooth finishing

- Cost effective

- Precision design

Frame

Dual Speeds Motor are supplied in a robust, rugged cast iron frame with integral feet. On Request we can supply motor in aluminum body up to 100 L frame.

Duty

Our dual speed Motor is suitable for Continues duty (S1) Short time duty (S2) Intermittent periodic duty (S3) Intermittent duty with Starting (S4)

Insulation

All dual speed motor is supplied with ‘F’ class insulation but temperature rise restricted to ‘B’ class.

Protection

We are supplying motor with Ingress protection 44 as defined in IS: 4691. Motors can be supplied with IP-54 and IP-55 on request.

Shaft

Shaft are Made from high carbon steel to provide exceptional Strength & rigidity to minimize deflection.

Rotor

Rotors are of high-pressure E.C. Grad aluminum die-cast. Every rotor is dynamically balanced. It’s made motor low amplitudes of Vibration & noise.

Bearings & Lubrication

Bearings are adequately lubricated with lithium based high temp up to 150 deg. All Dual Speed motor are supplied with C3 ball bearing & fully charged with lithium base grease at the time of assembly.

Enclosure

Two Speed Motor Supply with Enclosure T.E.F.C. (Totally Enclosed Fan Cooled).

Thermal Overload Protection

We can also supply Two Speed Motor with T.O.P Switch on Demand of Customer. It can provide motor extra safety form over lord protection.

Terminal Box

Dual speed Motor Supply with Terminal box on top position For Foot mounted (B3). Others position box like left or right supply on customer request.

Earthing terminals

Motor provided with minimum two earthling terminals. One in the terminal box and other on foot.

Paints

All motor is painted with semi glossy synthetic enamel paint. However, sp. Paint is available on request.

Applications

Dual speed motor is use in Many applications which multiple speeds are required. Pharmaceuticals, Crane, hoist, lift, construction, Chemical industries, Food equipment, Ceramic industries Machine tools for different application. We can also provide dual speed gear motor, dual brake motor.