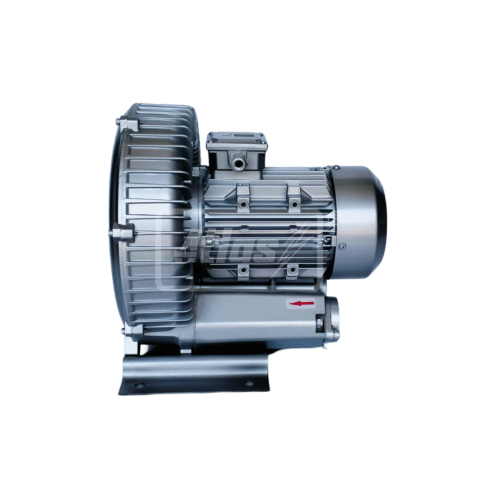

Ring blower

| Category | Details |

|---|---|

| Company Name | AMIT ELECTRICALS |

| Brand | Atlas |

| Product Name | Ring Blower |

| Operation | Operates using centrifugal force with a high-speed impeller generating continuous airflow |

| Range of Production |

Three Phase: 0.25 To 7.5 HP (0.18 to 5.5 KW) – 415 ± 5%, 50 Hz ± 3%. Also available in 220, 380, 460, 525 V at 50 or 60 Hz. Single Phase: 0.5 To 2 HP (0.18 to 1.5 KW) – 215 ± 5%, 50 Hz ± 3%. Also available in 110 V at 60 Hz. Maximum pressure range: 100 to 650 mbar. |

| Mounting Types | Foot (B3) |

| Frame Material | Pressure die-cast housing for strength and durability |

| Insulation | Class F insulation; fully impregnated with high-grade varnish |

| Ratings | S1: Continuous Duty |

| Voltage & Frequency |

Standard: 415 ± 5%, 50 Hz ± 3% Optional: 110, 220, 380, 460, 525 V at 50 or 60 Hz |

| Protection | Standard design includes noise-reducing silencers at inlet and outlet ports |

| Shaft & Rotor | Impeller made of lightweight, durable aluminum alloy with radial blades |

| Bearings & Lubrication | Self-lubricating bearings with high sealing efficiency |

| Thermal Overload Protection | Available on request |

| Terminal Box | Top position for Foot mounted (B3); other positions available on request |

| Earthing Terminals | Minimum two: one in terminal box, one on foot |

| Application |

Air circulation in HVAC systems Irrigation systems Dust control Vacuum systems (packaging & printing) Cooling & drying machinery Medical equipment support |

| Features |

High efficient Compact design Durable Smooth finishing Economical price Precision design Long Life |

Product Features & Configuration

Amit electricals are manufacturer, Supplier and Exporter of Ring Blower In brand “ATLAS”. It also knows as regenerative blower or side channel blower, is a device used to create airflow for various industrial and commercial applications. It operates using centrifugal force, where a high-speed impeller spins within a housing to generate continuous airflow.We are manufacturer Single stage and double stage Ring blower or side channel blower.

RANGE OF PRODUCTION

Three Phase

0.25 To 2 Hp. (0.18 to 7.5 Kw) Three Phase Ring blower suitable for 415 ± 5% volts 50 HZ ± 3%. We are also capable for Manufacturing three phase motor in different volts Like 220, 380, 460, 525 and 50 or 60 frequencies. Ring blowers are designed to operate at high pressure compared to standard centrifugal fans. The maximum pressure they can achieve typically ranges from 100 to 650 mbar

Single phase

0.5 To 2 H.P. (0.18. to 1.5 Kw) Single Phase Ring blower suitable for 215 ± 5% volts 50 HZ ± 3% we are also able to Supply motor in 110 volts on HZ 60 Also.

Impeller

A high-speed rotating impeller with radial blades is the core of the blower. It is usually made of lightweight yet durable materials like aluminum alloy.

Housing

The impeller is enclosed in a precisely designed housing, which forms the side channel. This housing is often pressure die-cast for strength and durability.

Inlet and Outlet Ports

These ports allow air to enter and exit the blower. They are usually threaded and equipped with silencers to reduce noise

Bearings and Seals

The impeller is supported by bearings, which are often self-lubricating. Seals are used to prevent air leakage and ensure efficient operation

Winding Insulation

Ring blower Winding are protected with insulated with class ‘F’. Fully impregnated with high-grade insulating varnish for tropical climate.

Duty

Ring blowers are Design for Working Continuous (S1) rated to comply with performance standards.

Application

Ring blowers are Use in Number of applications Like Air circulation in HVAC systems , Air circulation in HVAC systems, Air circulation in irrigation systems, Dust control in industrial settings, Vacuum systems for packaging and printing, Cooling and drying machinery or components Medical equipment support Ect.

Features

High efficient

Compact design

Durable

Smooth finishing

Economical price

Precision design

Long Life

Shaft Direction

All Single Phase Motor are supply with clock wise shaft rotation. It also possible of reveres Direction rotation. We are manufacture single reversible single phase motor.

Centrifugal Switch

Centrifugal switch is hart of Single phase motor. A centrifugally operated automatic Mechanism used in conjunction with split phase and other type of single-phase induction motors. Centrifugal cutout switches will open or disconnect the starting winding when the rotor has reached a predetermined speed and reconnect it when the motor speed falls below it. Without such device, the starting winding is susceptible to rapid overheating and subsequent burnout.

Winding Design

Capacitor start induction run motors with high starting torques suitable for use in machine tools, small compressors, booster pumps, atta chakkis etc. Where high lord inertia and or frequent staring stopping is involved. Resistant start induction run motor with moderately high starting torques ideally suited for optimum performance in applications like commercial juicers, industrial sewing machine, surgical pumps ECT

Shaft & Rotor

Single Phase Motor Rotor is positive locking with Shaft key joint so that cannot move on high Full lord Torque. Shafts are made by En-8 or En-9 material. Single Phase motors are of high pressure E.C. Grad aluminum die-cast. Every rotor is dynamically balanced. Its make motor low amplitudes of Vibration & noise

Bearings & Lubrication

Single phase motor Bearings are adequately lubricated with lithium based high temp up to 150deg. All the motors are supplied with C3 ball bearing & fully charged with lithium base grease at the time of assembly.

Enclosure

Single phase motor Supply with Enclosure T.E.F.C. (Totally Enclosed Fan Cooling).

Thermal Over protection

We can also supply motor with T.O.P Switch on Demand of Customer. It can provide Single phase motor extra safety form over lord protection.

Terminal Box

All Single phase Motor Supply with Terminal box on top position For Foot mounted (B3). Others position terminal box like left or right supply on customer request.

Earthing Terminals

All Single Phase Motor provided with minimum two earthling terminals. One in the terminal box and other on foot.

Paints

All Single-phase motors are painted with semi glossy synthetic enamel paint. However sp. Paint is available on request.