Quality

Quality Control through every Step

Amit Electricals: Empowering Industries with Superior Quality and Tailored Solutions

- Stringent Quality Checks

At Amit Electricals, every motor and machine undergoes multiple layers of rigorous quality inspections to ensure they meet the highest standards of performance and durability. Advanced testing equipment and methodologies guarantee precision in every product we deliver. - In-House Testing Facilities

Amit Electricals is equipped with state-of-the-art tools for spectrometry, hardness testing, impact testing, and other critical analyses. Non-destructive testing methods like ultrasonic, magnetic particle inspection, and radiography ensure product reliability and safety. Certified Processes

Our quality management systems at Amit Electricals adhere to globally recognized standards like ISO, ASTM, ANSI, and NACE, reflecting our commitment to excellence. Industry certifications reinforce our dedication to providing superior quality products.Raw Material Excellence

Sourcing only premium-grade raw materials from trusted vendors ensures the unmatched durability and efficiency of Amit Electricals’ products. Regular audits of suppliers maintain consistency in material quality.- Continuous Improvement

Amit Electricals emphasizes lean manufacturing principles and continuous process optimization to minimize defects and maximize efficiency. Feedback-driven approaches help us refine our manufacturing and testing processes constantly.

Amit Electricals Manufacturing Advantage

Quality Assurance

Strict adherence to industry standards, ensuring every product delivers exceptional reliability and performance.Innovative Technology

Continual investment in R&D to adopt advanced technologies for cutting-edge solutions.Wide Product Range

Comprehensive offerings, including Vibrating Motors, Vibrator Motors, and Vibratory Motors, to suit various applications.Competitive Pricing

Industry-leading prices without compromising on quality or service excellence.Skilled Workforce

A team of dedicated professionals committed to delivering excellence at every stage.

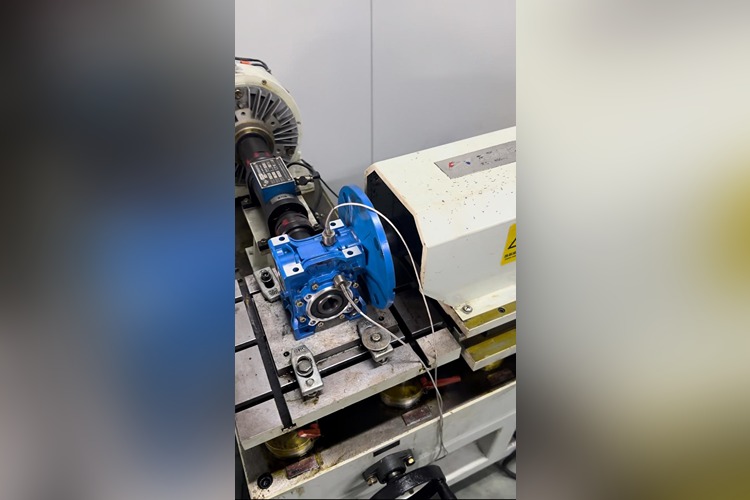

At RotorQ, we go beyond manufacturing. We rigorously test every motor and gearbox using a comprehensive suite of instruments to ensure peak performance and longevity. Here’s our testing arsenal:

- Micrometers (Outside, Dial Vernier, Digital Vernier): Guarantee exact dimensions for perfect fit and alignment

- Gear Tester, Worm Tester: Assess how well gears and worm drives perform under real-world loads.

- Sound Meter: Measures noise levels for smooth operation

- Deep Micrometer: Evaluates internal clearances for optimal performance

- Bore Gauge: Measures the diameter and roundness of bores

- Disc Micrometer: Measures the thickness of discs and other components

- Puppet Dial: Specialized instrument for intricate measurements

- CMM (TRIMOS): Coordinate Measuring Machine provides a 3D digital image for comprehensive quality analysis

Through this rigorous testing process, we deliver motors and gearboxes that consistently exceed expectations.

Quality Control at Amit Electricals: Ensuring Excellence at Every Step

Precision Manufacturing

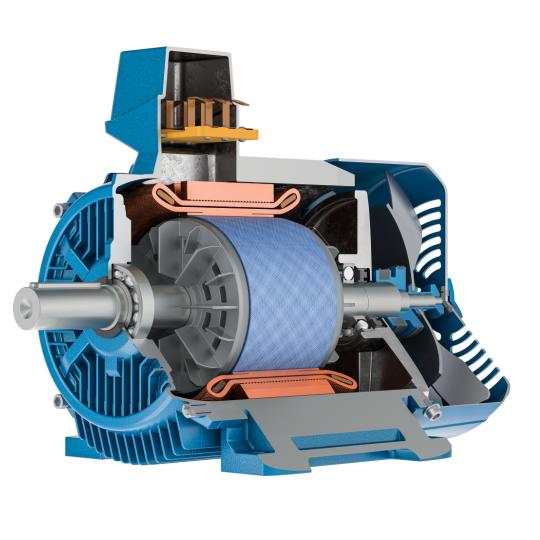

Our advanced machinery and skilled workforce work together to manufacture products with precise engineering, meeting exact specifications and tolerances.In-House Testing Facilities

Every product undergoes comprehensive testing in our state-of-the-art facilities, including performance, safety, and efficiency tests, to ensure it meets the highest standards.Real-Time Monitoring

Throughout the manufacturing process, real-time monitoring systems track every aspect of production, ensuring consistency and quality in each batch.Regular Audits and Inspections

We conduct regular internal audits and inspections to identify and correct any potential issues, ensuring continuous improvement.Comprehensive Product Evaluation

Before dispatch, all products are evaluated for functionality, durability, and safety, ensuring they perform optimally in real-world conditions.

Efficiency at Amit Electricals: Driving Optimal Performance

Energy-Efficient Designs

We prioritize energy efficiency in our motor and machine designs, ensuring that each product minimizes energy consumption without compromising on performance.Optimized Production Processes

Our streamlined manufacturing processes reduce waste, enhance throughput, and improve overall production efficiency, allowing us to deliver high-quality products in a timely manner.Advanced Technology Integration

We incorporate cutting-edge technologies and automation to boost operational efficiency, ensuring consistent product quality and faster production cycles.